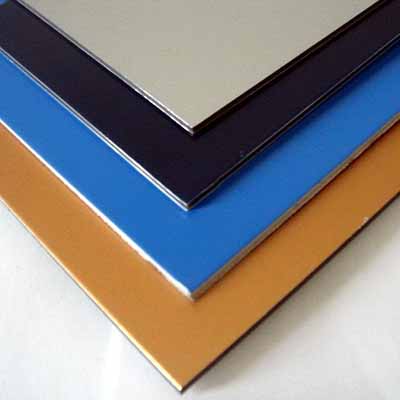

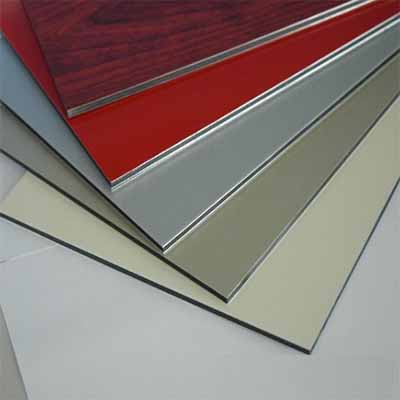

Composite aluminum panel consists of two layers of pure aluminum sheets, each with a thickness of 0.5 millimeters (0.2 to 0.25 millimeters for indoor use), and an intermediate layer of 3 to 4 millimeters of polyethylene (PE or polyvinyl chloride PVC). The layers are hot-pressed and rolled together to form a flat panel with specific dimensions, such as 1200mm×2440mm. The surface of the exterior composite aluminum panel is coated with fluorocarbon paint, applied through roller coating and simultaneously hot-pressed. The coating thickness is typically around 20 micrometers. The advantages of composite aluminum panels include being lightweight, having a smooth surface, excellent flatness, and no color deviation in the same direction. Additionally, they exhibit outstanding on-site processing capabilities. These panels provide conditions for addressing variations in external wall dimensions caused by on-site construction errors, thereby reducing workshop processing cycles and shortening installation periods.